J41B ammonia globe valve has stable sealing performance, safe and reliable use, strong corrosion resistance, no media leakage and lightweight operation, successfully solved the chemical pipeline with ordinary valves poor corrosion resistance, easy to perforate the shell as well as poor sealing performance, easy to leak the problem. Especially suitable for chemical industry ammonia, gas pipeline transmission, and to meet the requirements of long-term reliable use of its sealing, maintainability, safety and so on. Widely used in freezing, refrigeration, chemical, petroleum, food, smelting, liquefied gas and other industries.

Product Features

- To address the shortcomings of conventional valves—poor corrosion resistance and susceptibility to shell perforation—specialized ammonia valves utilize corrosion-resistant steel (low-temperature carbon steel alloyed with corrosion-resistant elements) tailored to the specific properties of the medium. This construction ensures resistance to ammonia gas and liquid ammonia corrosion, with a low-temperature tolerance down to -40°C, maximizing operational reliability under demanding conditions.

- The sealing pair configuration of ammonia shut-off valves employs a spherical-flat design with automatic sealing compensation, providing dual-safety assurance. This ensures stable sealing performance without adhesive wear, effectively resolving the issues of poor sealing and leakage common in standard valves for chemical pipelines.

- The flange incorporates a tongue-and-groove sealing structure, ensuring absolutely reliable sealing even under fluctuating pipeline pressures.

- The upper sealing assembly employs multi-stage PTFE sealing materials to form a composite seal, ensuring no medium leakage from the packing gland throughout the valve's service life. This eliminates the inherent weaknesses of conventional valve packing gland seals—such as susceptibility to leakage and potential accidents—that are prone to occur.

Product Parameters

Product Model | J41B-25C |

Valve Body Material | Cast Steel |

Nominal Pressure | ≤2.5Mpa |

Applicable Media | Ammonia, Ammonia Liquid, etc. |

Applicable Temperature | ≤150°C |

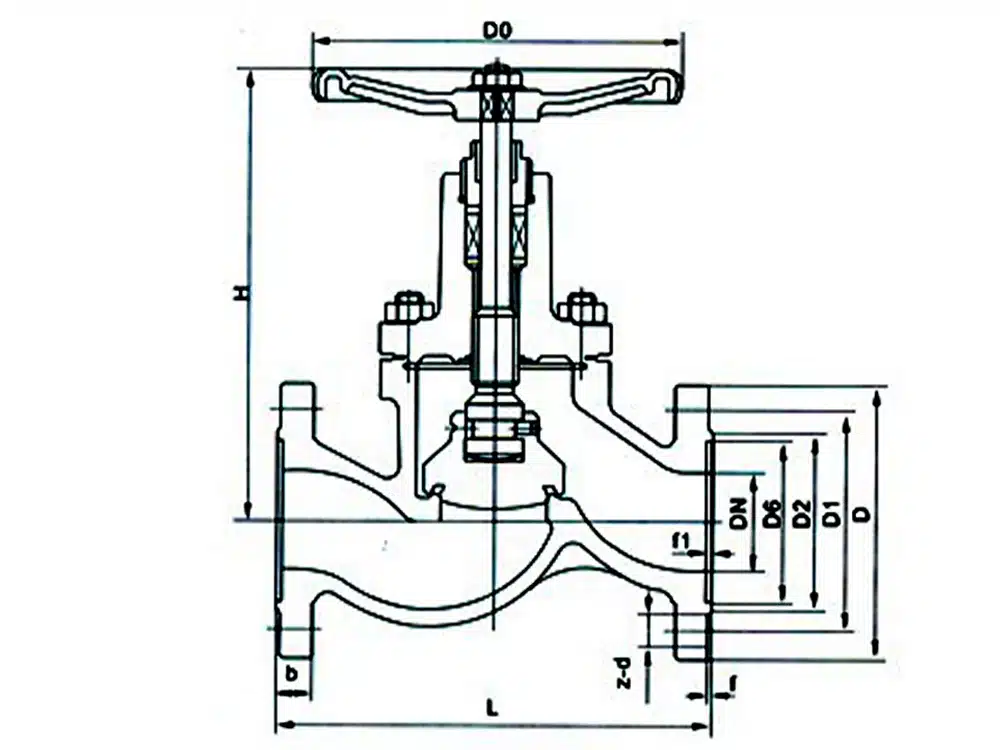

Product Size Reference

DN | L | D | D1 | D2 | D6 | b | f | f1 | z-d |

15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-14 |

20 | 150 | 105 | 75 | 55 | 51 | 18 | 2 | 4 | 4-14 |

25 | 160 | 115 | 85 | 65 | 58 | 18 | 2 | 4 | 4-14 |

32 | 180 | 135 | 100 | 78 | 66 | 20 | 2 | 4 | 4-18 |

40 | 200 | 145 | 110 | 85 | 76 | 20 | 3 | 4 | 4-18 |

50 | 230 | 160 | 125 | 100 | 88 | 22 | 3 | 4 | 4-18 |

65 | 290 | 180 | 145 | 120 | 110 | 24 | 3 | 4 | 8-18 |

80 | 310 | 195 | 160 | 135 | 121 | 26 | 3 | 4 | 8-18 |

100 | 350 | 230 | 190 | 160 | 150 | 30 | 3 | 4.5 | 8-23 |

125 | 400 | 270 | 220 | 188 | 176 | 32 | 3 | 4.5 | 8-25 |

150 | 480 | 300 | 250 | 218 | 204 | 32 | 3 | 4.5 | 8-25 |

200 | 600 | 360 | 310 | 278 | 260 | 34 | 3 | 4.5 | 12-25 |

250 | 650 | 425 | 370 | 335 | 310 | 36 | 3 | 4.5 | 12-30 |

300 | 750 | 485 | 430 | 390 | 364 | 40 | 3 | 4.5 | 16-30 |