H41W lift check valve is suitable for medium and small diameter pipeline under various pressures, temperatures and media to control the opening and closing device to connect or cut off the pipeline medium; rely on the self-weight of the valve flap and the fluid pressure difference to automatically stop the fluid backflow.H41W lift check valves are widely used in the fields of water treatment, chemical industry, petrochemical industry, petroleum, papermaking, mining, electric power, liquefied petroleum gas, food, pharmaceutical industry, water supply and drainage, municipal government, electronic industry, urban construction, environmental protection, fire fighting, heating and cooling, central air conditioning, filtration equipment and other fields. environmental protection, fire fighting, HVAC, central air conditioning, filtration equipment and other fields.

Structural Features

- Lift check valves offer advantages such as simple construction, reliable operation, and easy maintenance.

- When the medium enters the valve body in the direction indicated by the arrow on the valve body, the pressure of the medium acts on the valve disc, generating an upward thrust. When this thrust exceeds the gravitational force of the valve disc, the valve opens. When the force exerted on the valve disc by the downstream medium pressure, combined with the gravitational force of the valve disc itself, exceeds the force exerted on the valve disc by the upstream pressure, the valve closes, preventing backflow of the medium.

- The sealing surface is resistant to wear and abrasion, ensuring excellent sealing performance and extended service life.

Product Parameters

Product Model | H41W-16P |

Valve Body Material | 304 Stainless Steel |

Nominal Pressure | ≤1.6Mpa |

Applicable Media | Water, Steam, Oil, etc. |

Applicable Temperature | ≤150°C |

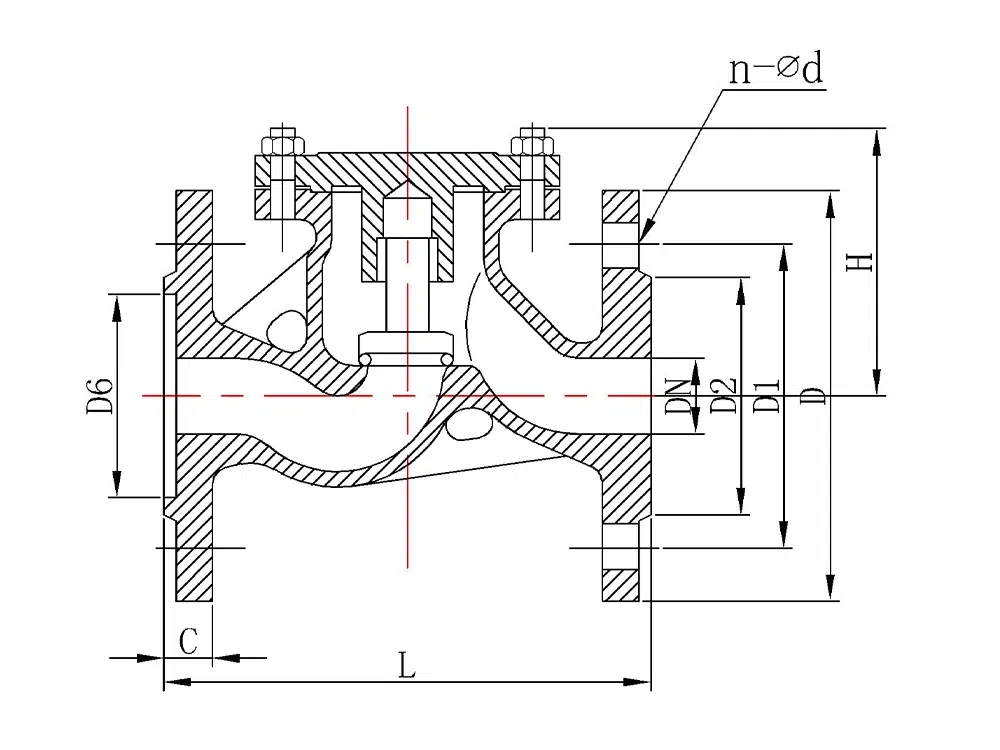

Product Size Reference

Nominal Diameter | L | D | D1 | D2 | C | n-∅d | H |

DN15 | 130 | 95 | 65 | 45 | 14 | 4-14 | 77 |

DN20 | 150 | 105 | 75 | 55 | 14 | 4-14 | 77 |

DN25 | 160 | 115 | 85 | 65 | 14 | 4-14 | 80 |

DN32 | 180 | 135 | 100 | 78 | 16 | 4-18 | 85 |

DN40 | 200 | 145 | 110 | 85 | 16 | 4-18 | 95 |

DN50 | 230 | 160 | 125 | 100 | 16 | 4-18 | 105 |

DN65 | 290 | 180 | 145 | 120 | 18 | 4-18 | 120 |

DN80 | 310 | 195 | 160 | 135 | 20 | 8-18 | 130 |

DN100 | 350 | 215 | 180 | 155 | 20 | 8-18 | 140 |

DN125 | 400 | 245 | 210 | 185 | 22 | 8-18 | 155 |

DN150 | 480 | 280 | 240 | 210 | 24 | 8-23 | 180 |

DN200 | 600 | 335 | 295 | 265 | 26 | 12-23 | 211 |

DN250 | 650 | 405 | 355 | 320 | 30 | 12-25 | 260 |

DN300 | 750 | 460 | 410 | 375 | 30 | 12-25 | 323 |

DN350 | 850 | 520 | 470 | 435 | 30 | 16-25 | / |

DN400 | 950 | 580 | 525 | 485 | 36 | 16-30 | / |