Analyzing the applicability of butterfly valves as control valves

Date: 2025-06-15 Categories: Valve Knowledge Views: 2048

Excerpt:

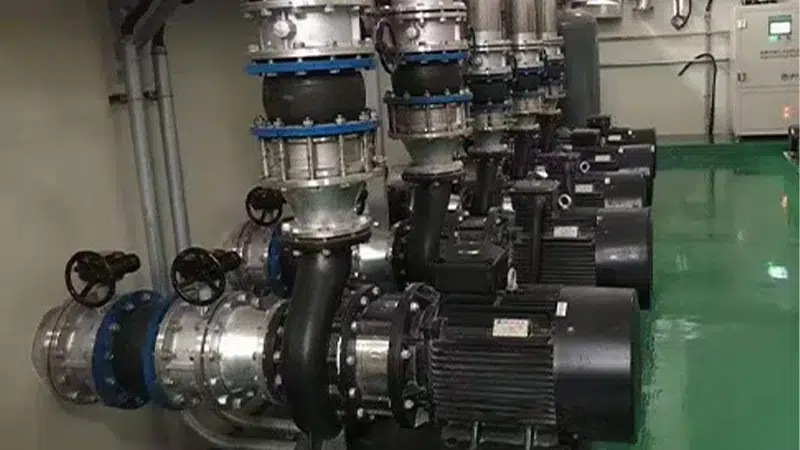

This paper evaluates the suitability of butterfly valves as regulating valves for fluid management in the industrial and construction sectors. The advantages of butterfly valves include simple design, small size, light weight, easy installation and maintenance, low operating torque, fast response and low flow resistance, which can reduce energy consumption and cost. However, its regulation accuracy is insufficient, the flow characteristic curve is nonlinear, and it is easy to cause flow fluctuation at small openings, and the sealing may decline and lead to leakage in long-term use. Therefore, butterfly valves are suitable for scenarios (such as ventilation or water supply and drainage systems) that do not require high regulation accuracy, have a wide range of flow variations, and emphasize cost and convenience; however, for high-precision demand scenarios (such as chemical production), ball valves or precision control valves are recommended.

In industry andconstruction industryFluid management scenarios in thecontrol valveThe selection of butterfly valves is extremely critical. To evaluate the suitability of a butterfly valve for use as a control valve, the following aspects should be considered.

The advantage of butterfly valve is its regulating function. Its simple design, small size and light weight make it easy to install and maintain. During operation, the butterfly plate rotates around the axis, requiring a small operating torque, which enables it to respond quickly to regulation commands and provide initial control of fluid flow. In addition, the butterfly valve has low flow resistance, which helps to reduce energy consumption and lower operating costs.

However, when butterfly valves are used as regulating valves, their regulating accuracy is relatively low. Its flow characteristic curve is not ideal linear, especially in small opening, the regulation performance is not good, which may cause excessive flow fluctuation, and it is difficult to realize accurate flow control. In addition, long-term use and frequent adjustment may lead to a decline in the sealing performance of the butterfly valve, leading to leakage problems, which in turn affects the regulation effect and system stability.

In specific applications, butterfly valves can be a suitable choice for regulating valves if the requirements for regulating precision are not high, the range of flow rate changes is wide, and there are high requirements for the cost of the valve, installation space and ease of operation. For example, in the field of ventilation system, water supply and drainage system, butterfly valve is sufficient to meet the basic regulation needs. However, for those occasions with extremely high requirements for flow control accuracy, such as precise metering and high-precision fluid transportation in chemical production, butterfly valves may not be able to meet the required standards, and should be considered at this time.ball valveThe valve is a precision control valve, and other types of control valves.