No related content

Products

About

Nesfo Valve Manufacturing (Quanzhou) Co.

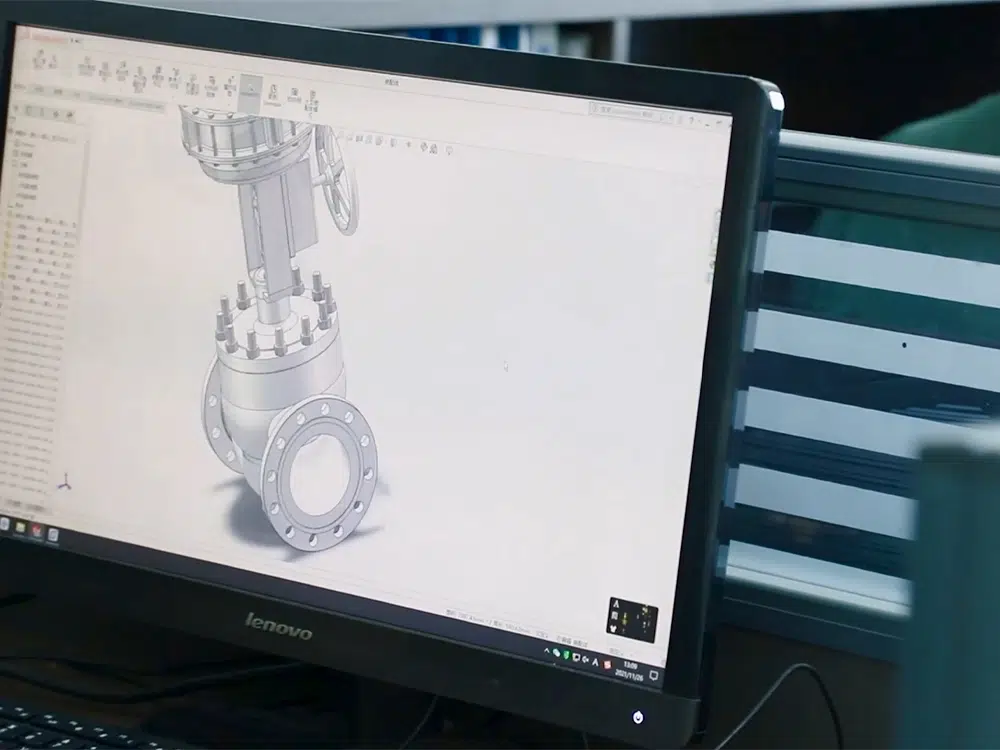

Nesfo Valve Manufacturing (Quanzhou) Co., Ltd. is an emerging enterprise in the valve industry, which integrates research and development, manufacturing, sales and service of fluid equipment.

The company mainly develops and manufactures: ball valves, butterfly valves, gate valves, globe valves, check valves, filters, water control valves, safety valves, pressure reducing valves, respiratory valves, regulating valves, pneumatic valves, electric valves and so on.

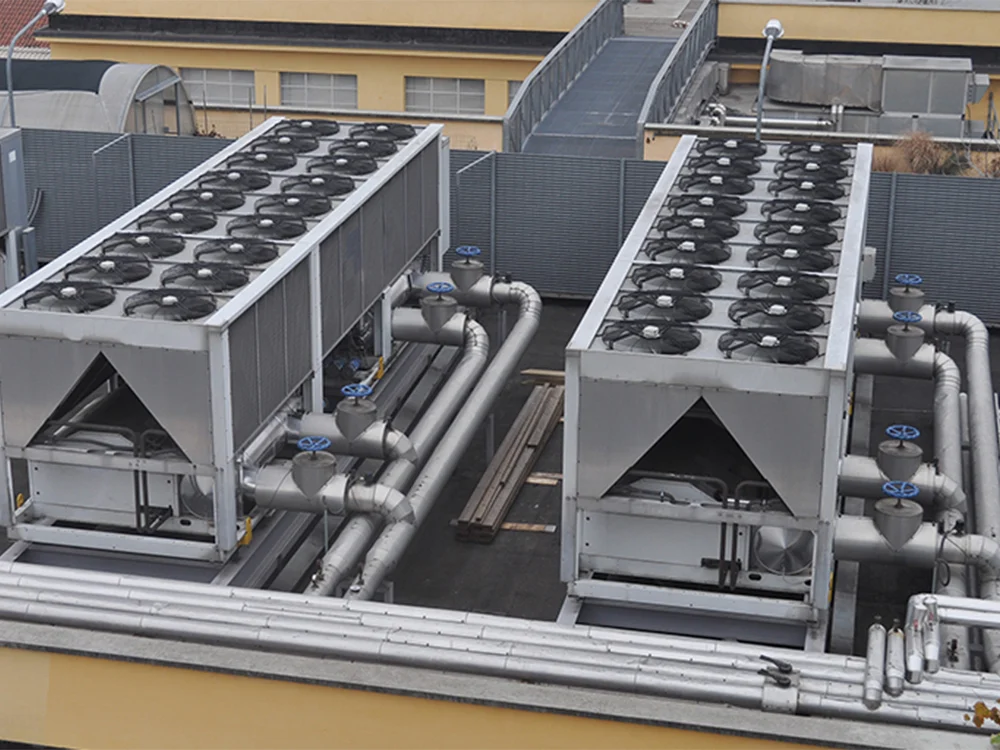

The products mainly serve in: heating, water diversion, urban water supply and drainage, sewage treatment, environmental protection, electric power, petroleum, chemical industry, buildings, ships, pharmaceuticals, metallurgy, fire and other fields.

Service Guarantee

Determine the type and specifications of valves based on the customer's actual requirements, or design and customize valves according to the customer's special requirements. Provide the customer with the valve design process and manufacture valves that meet the customer's requirements. We can also train the customer's technical personnel to ensure they have a basic understanding of technical knowledge and valve maintenance skills. Provide technical consulting services for new, special, and challenging engineering projects or develop appropriate construction plans.

Industry Applications

News

Contact Us

If you have any further questions, please leave us a message online and we will get back to you as soon as possible. If you would like more detailed information, please contact us directly via the email address below.

We will provide:

- 30-minute quick response, reply within 24 hours after leaving a message

- Customized solutions tailored to customer needs

- Keep track of the product production process at all times and shorten the production cycle as much as possible.

- Guide customers through installation and debugging, and provide quick after-sales response.

E-mail inquiries:[email protected]